Notes from the Field - "Cherokee" Huckins Restoration Project

30 April 2002

The late April air sparkles with the prickly glint of sanded fiberglass, as the crew continues their work on the hard top. Because of problems with over-heating epoxy, the crew covered the work area with tarps, and tackle the job early mornings. Three layers of Divinicell foam are being epoxied together panel by panel atop the form. Electrical wiring conduit was embedded in the second layer, fiberglassed over, and sanded. The last layer will be glassed as well, and sanded. "The whole top should weigh about 1,600 pounds," said Leonard "I Just Do What I'm Told" Yeomans. Once ready for placement, the crew will call on George Brown and his Super Crane.

Leonard Applying a Wave of Epoxy on Divinicell Panel

Crew Placing a Divinicell Panel, Conduit and Light Fixture Holes on Hard Top - Far Right Section Fiberglassed

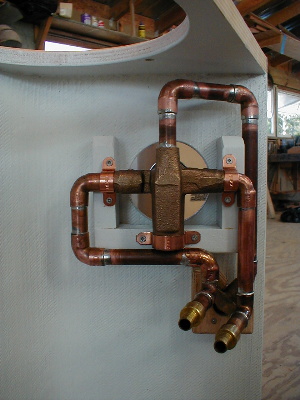

Bryan constructed the forward discharge manifold, where all the bilge pumps, watermaker, air-conditioning and sump-pump discharges will go. Tom Kirmeyer and Leonard attached the various hosing, making this quite a "medusa" fixture. The manifold is located beside the washer.

Forward Discharge Manifold

Tom Kirmeyer has the equipment room looking ship-shape, and reports that "everything is close to being squared-away." He'll be glad to emerge from that tight space once and for all. He's also been working on Cherokee's plumbing and piping, enabling him to uncurl his body and stretch his legs.

"Tom's Room"

Other Tom is making strides in building the shower mixing chambers for hot and cold water, which involves sweating copper and making use of capillary action. There are four chambers on the vessel - the one depicted below is for the crew's head.

Tom Parker's Marvelous Mixing-Chamber Magic

The stainless steel sinks, faucet, and shower fixtures are getting installed. The chrome-plated, brass faucets are from "Sign of the Crab" Company in California. Shown below is the sink in the master bath vanity, and the crew's head.

Pretty Head Fixtures

Tom Parker also installed the sliding pocket door for the master head, and is beginning the trim work in the master stateroom. Meanwhile, the rest of the crew sands, sands, and sands some more.

Fitting the Pocket Door

Yankee elvers are invading North Carolina, thanks to Jones County's economic initiative to bring new businesses into their depressed area. Elvers have nothing to do with fairies, brownies or Middle Earth, but are simply teenage eels. Since late 1999, Jones County lost two major apparel factories and some hog farms, reducing the number of manufacturing jobs from 300 to 34. "Our eel farm will provide badly needed jobs," Alexis Blanchard told the fisheries commission, requesting permission to transport and possess elvers. "We will purchase them in Maine (where, unlike NC, they have a commercial elver season), grow them to six inches in fiberglass holding tanks, and sell them to bait shops." Adult American eels, with a lifespan of up to 85 years, sneak off to the Sargasso Sea to spawn. The larvae travel back to rivers, streams and estuaries, and become two-inch transparent "elvers". For the next twenty years, they grow into slimy adults. At some unknown point they then morph into saltwater creatures with deep-water gas bladders, new coloring, and ocean-vision (retinas become sensitive to blue light). They head out to sea, where the females, ovaries engorging their entire body cavity, await the males to take the initiative to spawn amid the sargassum weed. Then they die.

Signing off for now,

Barbara "Fish Doctor" Blake